BH - Nano

BH - Nano

| Destined mainly for local markets, such as the smaller towns of mainland Greece or island areas. Such systems may well be used as trial (pilot) units in larger breweries. They are generally manually operated with a possibility of automation if desired. |  |

| Model | ΒΗ - Ν250 | ΒΗ - Ν500 |

| Capacity | |

250Lt/brew | 500Lt/brew |

| Daily Production | |

Up to 3 brew/24h(depending on the produced product) Up to 5 brew/24h with extensions |

|

| Annual Productivity | (24h/200 working days.) |

1.500 - 2.500hl | 3.000 - 5.000hl |

| System structure | |

Mixing | brewing | spinning container – Filtration container – Access platform and ladder – Malt | wort pump - Duplex wort cooling exchanger – Piping networks and valves – Hot liquor tank

|

|

| Heating system | |

Electric superheated water boiler ή or superheated water boiler with a diesel or gas burner | |

| Management system | |

Management system | Manually operated piping network valves and switchboard with the system controls (thermostats, motors, pumps) | |

| Automation | |

A Siemens PLC can be installed as an extension with a 6 inch touch screen to execute the extraction / brewing program and the operation of the system motors and pumps | |

| Expandability | |

Up to 4 containers with the addition of one brewing container and one spinning container | |

The configuration of beer brewing systems is flexible and is defined by the customer requirements, while maximum productivity is set after the definition of the final configuration.

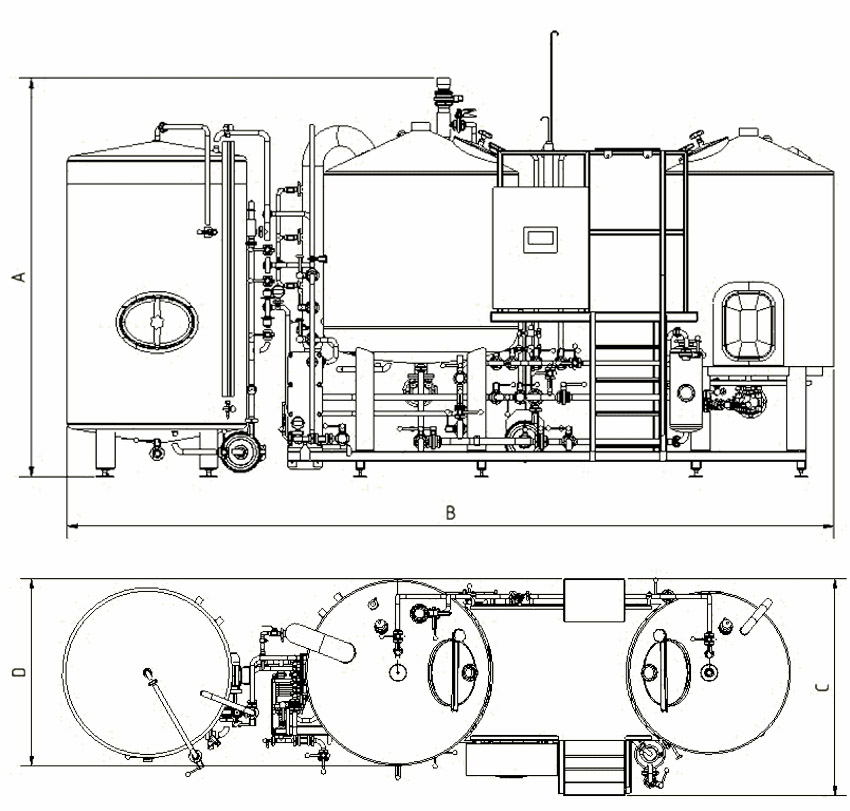

dimension

Various dimensions and models are available on order